CATHODIC PROTECTION

Of metallic structures

Principle

The set-up of a cathodic protection (CP) system allows stopping all the corrosion phenomena affecting the metallic structures, as described in the page Diagnosis, and preventing them to occur again. Preventively installed, it allows avoiding them.

The principle of CP is to make the entire surface of the structure to protect cathodic compared to an anode used as consumption piece.

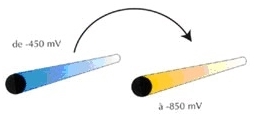

There are many criteria for CP, the most commonly admitted being the lowering of the oxidation potential of iron to a value of -850mV compared to a copper sulfate electrode (Cu/CuSO4).

The lowering of the potential can be achieved only by a "current input" from the electrolyte to the surface to be protected.

CP is only applicable to metals in contact with an electrically conductive medium, which excludes the mitigation of gaseous corrosion or atmospheric corrosion.

Three cases of application are presented below :

CP of reinforced concrete

Goal

In the case of reinforced concrete, CP is installed to stop the corrosion of metal reinforcement. When preventively installed during construction, CP allows avoiding all the corrosion mechanisms. At this stage, its cost is limited, as the installation before the concrete is poured is quite easy.

This type of protection is recommended for any reinforced concrete construction to be long-term protected, particularly when the concrete is submitted to an aggressive environment: presence of chloride or other corrosive products, presence of stray current, ... or when the concrete cover or its quality are insufficient.

Typical examples are sedimentation tanks, swimming pools, water towers, road structures exposed to de-icing salts, salts storage facilities, sea-side constructions, ...

We have specifications for this type of structures, that we can provide you on your request.

When curatively installed, CP can restore initial alkaline conditions of reinforced concrete, allowing the metal passivation and preventing corrosion. Unlike the traditional techniques requiring the removal of all the concrete parts with compromised chemical equilibrium, CP allows lighter repairs.

Its application will indeed restore this equilibrium in the whole structure, without mechanical intervention.

Installation: principle and systems

CP consists in applying an electric current to counter the current produced by the electrochemical corrosion reactions. This current prevents the movement of chloride ions and increases the pH of concrete, restoring the initial alkaline conditions and passivating the metal reinforcement.

Practically, direct current is supplied by a rectifier specifically programmed for the installation to which it belongs. The current is applied to the structure by an anodic system. The reinforcement metal rods become cathodic, and are thus protected against corrosion.

Identical on the principle, existing CP systems only differ from each other by the type of anodes used.

Here are 5 of them :

Metal mesh : the anode consists of a mesh of titanium coated with metal oxides and enclosed in a mortar. Ideally, this type of anodes is preventively installed during the building construction.

Conductive organic coatings : primary anodes (wires anodes) are fixed to the concrete surface and coated with a conductive polymer providing a better current repartition. The whole is then painted with a conductive paint. This system is more flexible and can be easily mounted on existing structures.

Strips of anodic mesh : the anode consists of strips of titanium mesh, positioned in grooves sealed with hydraulic mortar. This process allows the application of metal mesh (more resistant) to existing structures.

Conductive mortars based on modified hydraulic binder : primary anodes are fixed on the concrete surface and covered with a conductive mortar. This system requires a very good mixing of this mortar, which is often a practical problem.

Internal and/or local anodes : Anodes (for example a folded mesh) are inserted in cavities drilled in concrete. Cavities are then filled in with a mortar or a polymer ensuring the good distribution of current inside the concrete.

Control and management

The correct functioning and obtained results are controlled by computer, occasionally by on-site visit of one of our technicians, or more frequently by teleprocessing. The rectifier can be indeed remotely surveyed and controlled via modem.

Cathodic protection of buried structures

CP is frequently used to protect gas networks, long distance pipelines, tanks and buried networks of tank stations and water networks.

In this field, 2 categories of CP systems are available :

Active protections

CP by "current sampling" consists in connecting the structures to protect to the negative pole of a DC power supply, the positive pole being connected to an anode ground bed in contact with the same electrolyte as the structure. DC current supplied by the generator is diffused into the electrolyte through the anode ground bed and collected by the structures to protect, which are then set to an electronegative potential compared to the ground.

Passive protections

This method is generally used to protect small length structures, or in very low resistivity media. A galvanic coupling is created between the piece to protect, which will be the cathode of the galvanic cell, and an anode made of a metal soundly selected for its electronegative potential compared to the structure to protect.

Most commonly used metals for the anode are Magnesium, Zinc or Aluminum.

Control and teleprocessing

The correct functioning and obtained results are controlled by computer, occasionally by on-site visit of one of our technicians, or more frequently by teleprocessing. The rectifier can be indeed remotely surveyed and controlled via modem. An efficiency control is necessary once a year to check that the required potential is actually reached at every measurement points foreseen on the structure.

Cathodic protection of tanks

Tanks CP is based on the same principles as for buried structures, the electrolyte being inside the metal structure instead of outside.

Particularly it can be applied to :

Hot or cool water tanks, seawater, pure water of sanitary water (the system does not alter the quality of drinking water) ;

Sand filters ;

Tanks or collectors with variation of water level ;

Sludge thickeners ;

Storage tanks.

New tanks that are correctly treated and protected by CP will be nearly immune to corrosion.

To achieve this result, it is essential to keep the installation under close monitoring, at least annually.